●

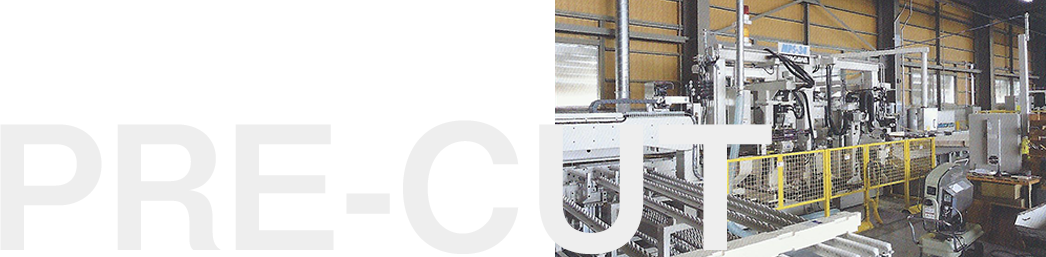

Within post & beam method construction , an approach said to require four workers per each 3.3 square meters through finishing, the making process is reduced to around one-fourth the previous level .This effectively transforms the most demanding portion the work into the pre-cut mode.

●

Plant-based structural materials processing brings a major boost in efficiency over the conventional manual processing approach.

●

Machine processing raises work precision, with quality control spearheading impressive improvements in the quality and performance of the finished homes.

●

The time and trouble involved in gathering, procuring and selecting timber is dramatically reduced, with products directly delivered from the pre-cutting plant to the construction sites.

●

Joints, connections, coupling positions and other processing methods are integrated, making it possible to compile manuals that better guide the construction work.